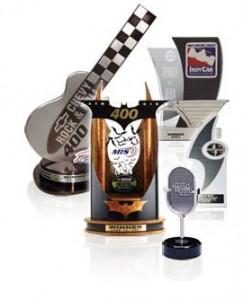

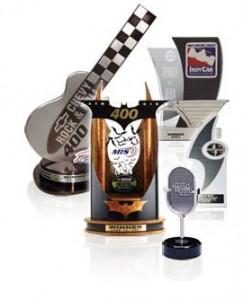

No one in the industry can compete with what we do at Bruce Fox, Inc. Over the course of over 80 years, we have continually adapted and innovated to ensure we offer the widest range of manufacturing possibilities.

Fabrication

Our ability to fabricate—render by hand a wide assortment of substrates and materials—is perhaps the single-most distinctive feature of Bruce Fox manufacturing.

We have a studio environment where many “museum-quality” awards take shape by way of drills, lathes, saws, routers, etc. Computer plotting, jigs, and other tools aid in the precision machining our work requires. But the most effective tool is the skill and experience of our craftspeople.

Electroforming (Engle)

The Engle is a Bruce Fox exclusive, by which parts are electro-formed in pure copper in large plating tanks—molecule by molecule—using special molds created at Bruce Fox.

The Engle is equal parts art and science, with experienced and trained technicians/craftspeople balancing the aesthetics with chemical engineering, electrical engineering, and physics.

Cast Urethane (Foxite)

Foxite is another Bruce Fox exclusive. It is a specially-formulated, high-density polyurethane resin compound that is cast by hand in highly-detailed rubber molds created at Bruce Fox.

Foxite can be molded in nearly limitless shapes with a high fidelity of detail. It is extremely durable, and can be machined and finished in a variety of treatments.

Metal Etching

Opaqued metal is exposed to a wash of carefully formulated acid (during which exposed bare metal is essentially “dissolved” chemically.

Full Color UV Direct Imprinting

A large-scale printing device imprints in high-resolution full color directly on a variety of substrates, including—but certainly not limited to—wood, glass, acrylic, Plexiglas, sintra, and PVC. Just about any flat, non-porous substrate can be imprinted.

Pewter Spin Casting

Pewter spin casting—also known as centrifugal casting—is a method for creating flat-backed appliqués in large volume. At Bruce Fox, we work with a variety of pewter alloys.

Molten pewter is poured into rubber molds as they spin. The spinning action creates an air-free flow of metal into the outer mold areas via centrifugal force. The flow gates and plug are cut away and re-melted, so material usage is very efficient.

Spin castings can be finished in a variety of ways, including plated, painted, color-filled, and antiqued.

Bronze Investment Casting

Bronze investment casting is a centuries-old technique in forming molten metals in dimensional shapes. A wax model of each part is cast in a rubber mold—the rubber mold is derived from a pattern we render here at Bruce Fox. The model is enveloped in a flask of special plaster called investment.

After the invested flask cures, the wax is melted out of the center of the mold. The resulting cavity within the investment is then filled, using a vacuum-injector, with 2100-degree molten bronze. Once the metal cools, the investment material is broken away, revealing a raw, solid metal casting.

Bronze & Aluminum Sand Casting

Sand casting is produced by pouring liquid metal into a mold made of a mixture of silica sand, clay, and other additives packed around a pattern in order to form a mold cavity. After the mold has been compacted, the pattern is withdrawn and molten metal is poured into the remaining mold cavity. When the metal has solidified and cooled, the casting is separated from the sand mold and is ready for finishing.

Die Casting

Die casting is the process of forcing lower-grade molten metals (typically zinc) under high pressure into mold cavities. This process is used to create small to medium sized parts, with good detail, fine surface quality and dimensional consistency. Ideal for projects with ample extended lead times and larger production runs.

Glass Etching, Lasering & Fabrication

Etching glass involves wrapping each piece with a protective film, called resist, which has been photo-processed with the image to be rendered on the glass.

In this area, we also assemble glass to other components—glass, marble, metal, etc. The exact right amount of bonding fluid in the exact place exposed to the UV curing light for just the right amount of time will result in a flawless, invisible bond that is, in most cases, stronger than the media being put together.

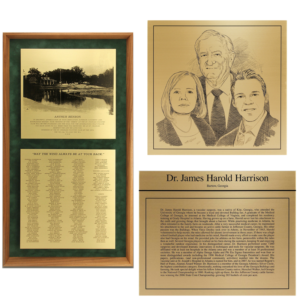

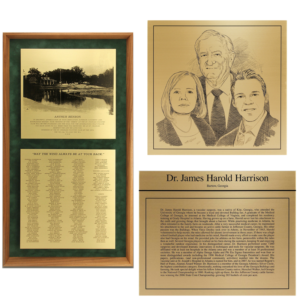

Woodworking

Bruce Fox, Inc. includes a full-scale woodworking operation, with every imaginable industrial machine producing various panels, bases, frames and other parts. Our wood shop also machines acrylic and urethane materials in much the same manner as wood components.

Metal Plating

Bruce Fox, Inc. is also a traditional metal-plating operation, where components of all types are given decorative plated finishes in bright and satin coppers, brasses, nickels, silvers and karat golds.

Silkscreening

Specially-formulated inks are applied to a surface through film processed templates. These templates are fine screens, with up to 300 openings per linear inch, which have been masked in a photo-development process. Silk-screening can obtain very clean and opaque images on a variety of substrates.

Dye Sublimation

Dye-sublimation is a four-color process by which inks are heat-transferred onto a specially-coated surface. The inks are sublimated in the process, meaning they are chemically induced into the surface, not imprinted on the surface.

Laser Cutting & Marking

We are utilizing state-of-the-art lasers to render images in a variety of substrates. We also use our lasers to cut out parts, as well as masks and other tooling components we use for other manufacturing departments.

Material Finishing

Metal Finishing

Jewelry-quality polished and satin finishes are hand-rendered by experienced artisans. Abrasives, compounds, solvents and proper machinery are essential, but the human factor is the most critical for obtaining a finely-honed, meticulous and consistent finish.

Lacquer Finishing

Exposed metals will quickly tarnish without a proper topcoat. We use a high-quality clear lacquer to give our crafted metal pieces a lasting quality finish.

Antique Finishing

Antiquing is the semi-opaque color that is added to the background of a dimensional figure for added contrast with the raised elements.

Paint Finishing

We work in a clean environment with a variety of spray- and hand-applied undercoatings, primers and finishes.

Product Personalization

Our operation includes a wide range of capabilities for inscribing names, titles and other unique text to the products we make. These capabilities include:

- Chemical etching

- Engraving

- Full-color UV imprinting

- Lasering

- Dye-sublimation

- Silk-screening

- Abrasive etching

Custom Work

Custom Work

Design Your Recognition (DYR) Logo and go

Design Your Recognition (DYR) Logo and go